Description

Check chain length is correct, as once we cut the chain there will be a fee to change.

If you require a length we don’t list, please just let us know.

All Chain Sets are assembled in accordance with the NZ Department of Labour code of practice and LEENZ guidelines and conforms with

Standards EN818.4, EN1677-1, AS3776.

All SLR components used clearly show the manufacturer name or brand, the manufacturers identification batch testing number, the size and component rating.

All of the larger 16mm & 20mm G80 Chain sets are assembled using Thiele Germany Lifting Chain

Instructions for use :

In general all grade 8 components should be inspected before use to ensure that :

• all markings are legible

• all items are free from nicks, gouges, cracks and corrosion

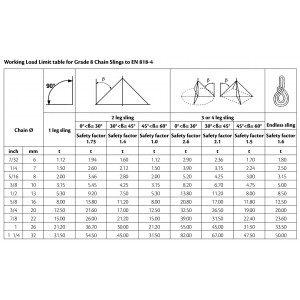

• items with the correct Working Load Limit have been selected with respect to the sling design i.e. the load to be lifted, the number of legs in the sling, the top angle etc. For further details, we refer to EN818 norm for chain slings

• items may not be heat treated as this may affect their Working Load Limit

• never repair or reshape an item by welding, heating or bending as this may affect the Working Load Limit

• master links and the other items of the sling are all identifiable as being of the same steel grade

• items should be used for straight in line loading only, this in order to avoid bending

• items are not distorted or unduly worn

It is required that the products are regularly inspected and that the inspection should take place minimally in accordance with the safety standards given in the country of use. This is required because the products in use may be affected by wear, misuse, overloading, etc. with a consequence of deformation and alteration of the material structure.

Inspection by a competent person should take place at least every 12 months and even more frequently when the components are used in severe operating conditions.